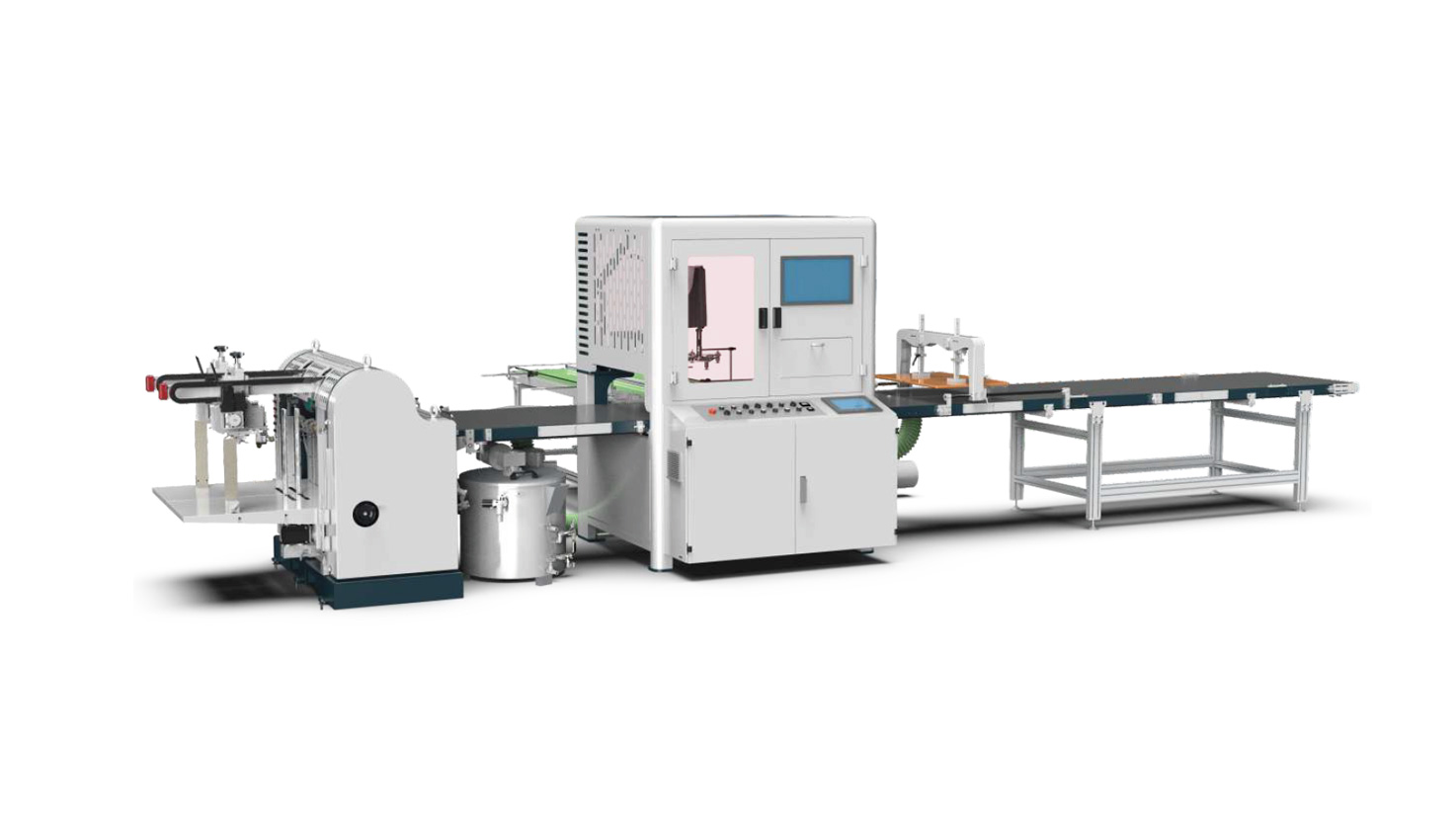

HM-600N Automatic Gluing and Spotter Machine Functional specifications

The HM-600N automatic gluing and spotter machine is

the latest model developed by our company. It is suitable for

the positioning process production of various box positioning

machines. It can produce top and bottom box at the same

time, realizes double-channel production and doubles the work

efficiency.

This machine adopts PLC and touch screen man-machine

control system and camera tracing system to realize automatic

completion of paper feeding, gluing and positioning. In feeder,

the glue and conveyor belts are driven by servo, which can be

infinitely variable, high precision, easy to adjust, and save time.

The positioning part adopts camera tracing system and robot

grasping parts to improve positioning accuracy and efficiency,

the error range is ±0.05mm, and the speed is faster。

HM-600N Automatic Gluing and Spotter Machine unit features and standard equipment

1. Suit to all kinds of paper and box shells positioning process;

2. Suit to all kinds of paper and cardboard positioning process (optional);

3. Parameter adopts computer digital setting;

4. Auto error stop and display;

5. Independent double feederAutomatic feed paper;

6. 24-hour glue timing heating function;

7. Servo system for controlling the whole machine;

8. Spotter by camera tracing system and SCARA (Selective Compliance

Assembly Robot Arm);(Details please check the note)

9. Automatic control system of glue viscosity (optional); (Details please check

the note)

The main technical parameters of HM-600N Automatic Gluing and Spotter Machine

Note: